Language

ENGWhat Are the Advantages of Using 90 Degree Hydraulic Flanges in Hydraulic Systems?

2024.08.12

2024.08.12

industy news

industy news

1. Space Efficiency

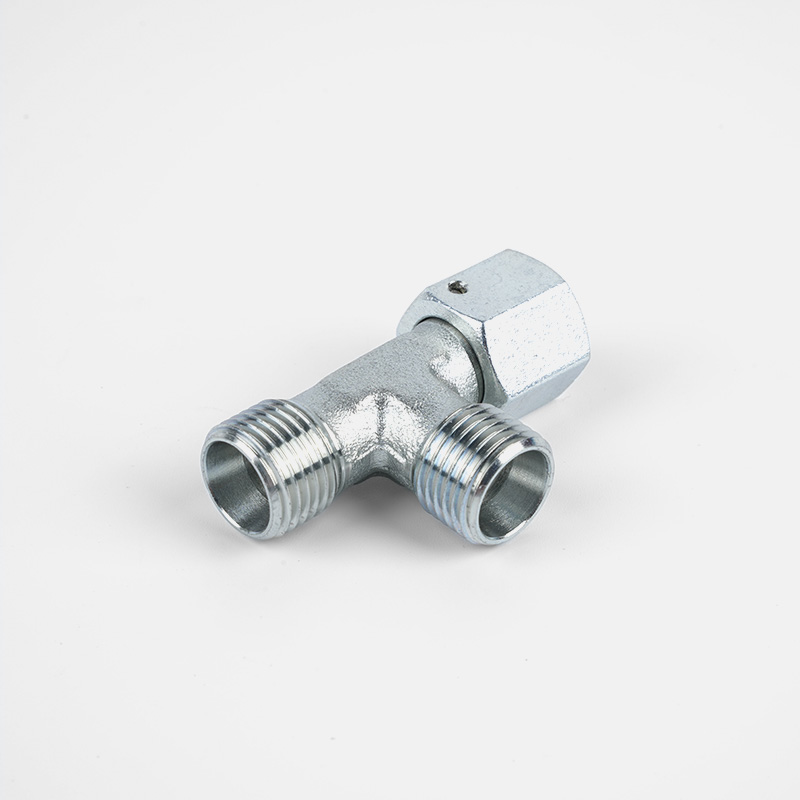

90-degree hydraulic flanges are indispensable for optimizing space within hydraulic systems. In many industrial settings, space is a premium, and efficient use of available area can be critical for operational effectiveness. Traditional hydraulic systems that rely on straight pipes often require extensive space for routing, which can be challenging in compact machinery or constrained environments. By incorporating 90-degree flanges, designers can achieve sharp turns and changes in direction without extending the length of piping or hoses. This capability allows for more compact and efficient designs, as the flanges eliminate the need for multiple connectors or complex routing. The reduction in the number of components and the ability to use vertical or horizontal space more effectively streamline the system, making it more manageable and easier to install. This space efficiency not only helps in fitting components into tighter spaces but also contributes to an overall cleaner and more organized system layout.

2. Reduced Risk of Leakage

Leakage in hydraulic systems can lead to significant operational issues, including loss of fluid, reduced system efficiency, and potential safety hazards. 90-degree hydraulic flanges are engineered to provide robust and leak-proof connections between hydraulic components. The precision with which these flanges are manufactured ensures a tight seal that effectively prevents fluid from escaping. This is achieved through careful design considerations, such as accurate machining and the use of high-quality sealing materials. By minimizing the risk of leaks, these flanges help maintain the integrity of the hydraulic system, ensuring that it operates smoothly and reliably. In addition to preventing operational disruptions, reducing leaks helps protect the surrounding environment from contamination and minimizes the need for frequent maintenance or refilling of hydraulic fluids. The enhanced sealing capability of 90-degree hydraulic flanges thus contributes to a more stable and reliable hydraulic system.

3. Improved Flow Efficiency

The flow efficiency of a hydraulic system is crucial for optimal performance, and 90-degree hydraulic flanges play a significant role in this regard. Unlike traditional pipe elbows or connectors, which can create turbulence and pressure drops, 90-degree flanges are designed to facilitate a smooth transition for hydraulic fluid. The flange's geometry is engineered to reduce resistance and maintain a consistent flow path, minimizing disruptions in the fluid's movement. This improved flow efficiency contributes to better system performance by ensuring that hydraulic fluid travels through the system with minimal pressure loss. As a result, the hydraulic system can achieve higher levels of performance and energy efficiency, which can lead to lower operational costs and improved overall functionality. Efficient flow also reduces the strain on pumps and other components, potentially extending their service life and enhancing the system's reliability.

4. Durability and Longevity

Durability is a key factor in the performance of hydraulic components, and 90-degree hydraulic flanges are designed to meet high standards of strength and resistance. Typically constructed from high-strength materials such as steel, stainless steel, or aluminum, these flanges are capable of withstanding significant pressure and harsh operating conditions. Their robust construction ensures they remain functional over extended periods, even in demanding environments. This durability is essential for maintaining system integrity and avoiding frequent replacements or repairs. High-quality materials and precise manufacturing processes contribute to the longevity of 90-degree hydraulic flanges, ensuring that they perform reliably throughout their service life. Investing in durable flanges not only enhances system performance but also leads to cost savings over time by reducing maintenance needs and extending the lifespan of the hydraulic system.

5. Ease of Installation

The ease of installation is a significant advantage of 90-degree hydraulic flanges. Their standardized dimensions and mounting patterns make them compatible with a wide range of hydraulic systems and components. This compatibility simplifies the installation process, reducing the time and labor required to set up or modify the system. Additionally, the straightforward installation process helps ensure that the flanges are fitted correctly, which contributes to the overall reliability and performance of the hydraulic system. For maintenance or system adjustments, the ease of removing and replacing 90-degree hydraulic flanges facilitates quick and efficient modifications. This user-friendly installation and maintenance process is beneficial for both initial setup and ongoing system management, making these flanges a practical choice for hydraulic systems.