Language

ENGHow important is the material selection and surface treatment of Female Reusable Fittings?

2024.07.12

2024.07.12

industy news

industy news

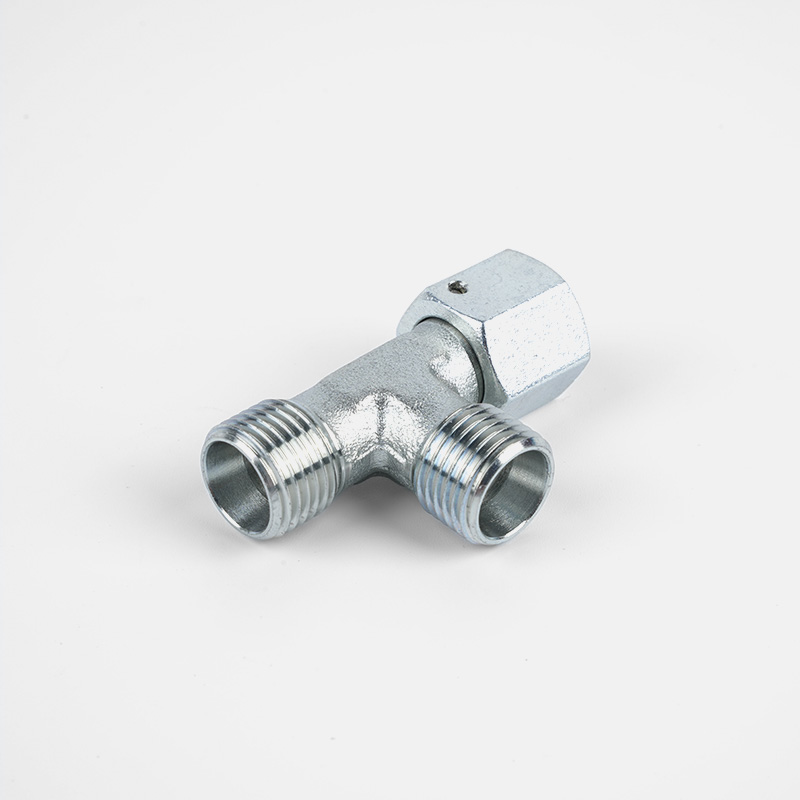

In complex industrial environments, the durability and flexibility of Female Reusable Fittings have gradually become an indispensable part of the connection fluid system. These joints bear the heavy responsibility of transmitting media and maintain stable performance and reliable sealing under harsh working conditions. All of this is inseparable from their carefully selected materials and surface treatment processes.

The material selection of Female Reusable Fittings is very important, which directly determines the strength, corrosion resistance and service life of the joint. Common materials include stainless steel, brass, carbon steel and special alloys. Stainless steel has become the first choice for many high-end applications due to its excellent corrosion resistance and high strength. Stainless steel joints can resist the erosion of a variety of chemicals, including acids, alkalis, salts, etc., ensuring stable performance in corrosive media. Brass is favored for its good processability and aesthetics. Brass joints are not only easy to process into various shapes and sizes, but also have high corrosion resistance and are suitable for general industrial environments. Carbon steel can also achieve high strength and corrosion resistance through processes such as heat treatment, but its cost is relatively low and is suitable for occasions with strict cost requirements. Special alloys should be customized according to specific needs to meet the requirements of use under extreme working conditions. These alloys usually have higher strength, better high or low temperature resistance, and stronger corrosion resistance.

In addition to material selection, the surface treatment of Female Reusable Fittings should not be ignored. Surface treatment can not only improve the corrosion resistance and wear resistance of the joint, but also increase its beauty and service life. Galvanizing is a common surface treatment method. Through galvanizing, a dense zinc layer can be formed on the surface of the joint, which effectively isolates air and moisture and prevents the joint from rusting and corrosion. The zinc layer can also act as a lubricant to reduce friction and wear between the joint and the hose or pipe. Nickel plating is a more advanced surface treatment method. The nickel layer not only has excellent corrosion resistance and wear resistance, but also can improve the hardness and gloss of the joint. The nickel-plated joint is more beautiful in appearance and can withstand more severe environmental conditions. In addition, there are a variety of surface treatment methods such as spraying and anodizing to choose from. These treatment methods have their own characteristics and can be selected and applied according to specific needs.